Composition and Application of Flexible Metal Hose

Composition and application of flexible metal hose

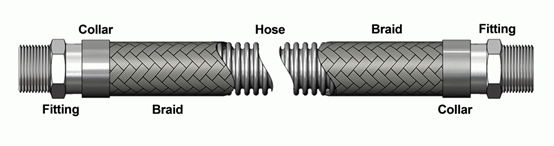

In order to understand flexible metal hose assemblies and how they serve various applications it’s best to review their anatomy. In its simplest form, a metal hose is made of four basic components:

• Corrugated tubing

• Braid

• Braid collars

• End-fittings

Separately, these parts are really quite simple. However, they can be customized to form a variety of configurations, enabling flexible metal hoses to be an optimal solution in a number of industries.

Flexible metal hose is an important connecting component in engineering technology, which is composed of corrugated tubing, braid, braid collars and end-fittings. It is used as compensation element, sealing element, connecting element and damping element in various gas transmission and infusion pipeline systems as well as length, temperature, position and angle compensation systems. It is used in aerospace, petrochemical, mining electronics, mechanical shipbuilding, medical and health, textile electronics, energy construction and other fields.

• Corrugated tubing

• Braid

• Braid collars

• End-fittings

Separately, these parts are really quite simple. However, they can be customized to form a variety of configurations, enabling flexible metal hoses to be an optimal solution in a number of industries.

Flexible metal hose is an important connecting component in engineering technology, which is composed of corrugated tubing, braid, braid collars and end-fittings. It is used as compensation element, sealing element, connecting element and damping element in various gas transmission and infusion pipeline systems as well as length, temperature, position and angle compensation systems. It is used in aerospace, petrochemical, mining electronics, mechanical shipbuilding, medical and health, textile electronics, energy construction and other fields.

High pressure flexible metal hose is a new type of product, which is used in harsh working conditions. As a kind of flexible pressure-resistant pipe, flexible metal hose is installed in the liquid conveying system to compensate the mutual displacement of the connecting ends of pipes, machines and equipment, and absorb vibration energy. It has the advantages of good flexibility, light weight, corrosion resistance, fatigue resistance, high and low temperature resistance, etc. It is widely used in the fields of water supply, water supply, chemical industry, chemical industry, textile, chemical industry, etc.

Function of flexible metal hose:

1. It can reduce the installation stress of the pipeline, compensate the movement of the rated position of the pipeline, and absorb the vibration of the pipeline system.

2. It needs flexible conveying pipe to prevent vibration. It can be used in steam, gas, air, petroleum and chemical industry.

3. The specification of stainless steel metal hose is a flexible component for conveying various media by weaving one or more layers of steel wire or steel belt net outside the stainless steel corrugated pipe, with joint or flange head at both ends.

Function of flexible metal hose:

1. It can reduce the installation stress of the pipeline, compensate the movement of the rated position of the pipeline, and absorb the vibration of the pipeline system.

2. It needs flexible conveying pipe to prevent vibration. It can be used in steam, gas, air, petroleum and chemical industry.

3. The specification of stainless steel metal hose is a flexible component for conveying various media by weaving one or more layers of steel wire or steel belt net outside the stainless steel corrugated pipe, with joint or flange head at both ends.